Efficient Glass Fabrication Cleaning Methods

Automating the cleaning process can significantly reduce the time spent maintaining grinding tools. Consider using automated cleaning systems to minimize manual intervention and keep tools in top condition.

- Ultrasonic Cleaners: Ultrasonic cleaning units use high-frequency sound waves to gently clean tools without damaging them. This method can quickly remove debris and slurry, keeping grinding tools free of buildup.

- Vibratory Cleaning Systems: These systems use vibration to dislodge dirt and dust from the grinding tools, making the cleaning process faster and more effective without interrupting production.

Wet grinding uses water or coolant to suppress debris during grinding, reducing the frequency and intensity of cleaning required. It also helps cool the tools, preventing overheating and reducing wear.

- Integrated Water Systems: Install automatic water-cooling systems that ensure a constant flow of water to the grinding area. With the addition of SwarfBuster, this keeps the grinding tools clean, cool, and reduces the particles that accumulate.

- Water Recycling Systems: Implement water recycling systems that filter and reuse water, allowing you to maintain consistent water flow while minimizing downtime for refilling or cleaning.

A continuous filtration system helps maintain clean water, reducing the risk of particles clogging the grinding tools and reducing cleaning time. Continuous water circulation also minimizes the build-up of abrasive material, which can negatively affect production.

- Closed-Loop Circulation: In a closed-loop system, the water is continuously filtered and recirculated, ensuring the water remains free from contaminants without requiring constant replacements or interruptions.

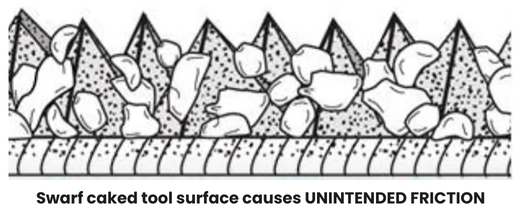

- SwarfBuster Additions: Introduction of SwarfBuster in the water circulation process alters the particle charge of the swarf, reducing the potential for excessive swarf build-up in pipes and corners of fall out tanks. SwarfBuster can reduce the need for frequent maintenance and keeps grinding tools from becoming clogged with debris.

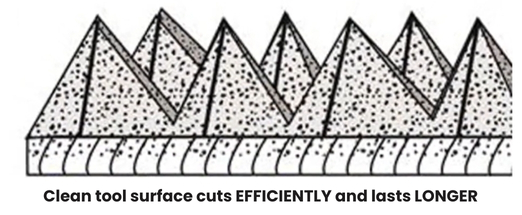

Choosing the right grinding tools can make a significant difference in cleaning efficiency and overall productivity.

- Diamond Grinding Tools: Diamond abrasives are highly resistant to wear and clogging, leading to less maintenance and longer tool life. These tools require less frequent cleaning and provide better performance, especially in high-volume production.

- Porous or Self-Cleaning Tools: Tools designed with porous surfaces or self-cleaning properties help to reduce debris buildup, which in turn reduces the frequency of cleaning required.

Proactively managing tool health can help reduce the time spent on cleaning and increase overall production time.

- Routine Inspections: Schedule regular inspections of grinding tools to catch any buildup or signs of wear before they affect production. This allows for cleaning or repairs to be done during planned downtime rather than causing unexpected interruptions.

- SwarfBuster: Typically added once or twice per day depending on production rates.

- Wear Sensors: Use sensors to monitor the wear level of grinding tools and water quality. These sensors can alert operators when tools need cleaning or replacement, preventing delays caused by unclean tools.

Improving the grinding process itself can reduce the frequency of tool cleaning and extend their use, thereby increasing production time.

- Optimal Speed and Pressure: Use the correct grinding speeds and pressures to minimize excess heat and wear on the tools. Overloading the grinding process with too much pressure can cause rapid buildup of debris, requiring more frequent cleaning.

- Adjustable Grinding Parameters: Use equipment with adjustable grinding parameters to ensure the process is tailored to the material and production requirements, preventing unnecessary tool wear and cleaning needs.

Well-trained employees can handle tools more effectively, preventing unnecessary dirt buildup and improving the efficiency of cleaning processes.

- Tool Handling and Cleaning Protocols: Train employees to follow best practices for handling tools, including proper cleaning techniques and maintaining equipment during production.

- Time Management: Instruct workers on how to balance tool cleaning with ongoing production tasks to minimize downtime.