Wet Cutting and Grinding of Plate Glass: Techniques, Benefits, and Best Practices

When it comes to working with plate glass, precision is key. Whether you’re crafting custom glass windows, mirrors, or intricate glasswork, wet cutting and grinding are essential techniques that ensure clean, smooth edges and precise shapes. In this white paper, we’ll explore the processes of wet cutting and grinding of plate glass, their benefits, and the best practices for achieving top-notch results.

What is Wet Cutting and Grinding?

Wet cutting and grinding refer to processes in which water is used during the cutting and smoothing of plate glass. Unlike dry cutting, where friction generates heat, wet cutting uses water to cool and lubricate the cutting surface. This prevents excessive heat buildup and reduces the risk of glass breakage. Similarly, wet grinding uses water to keep the grinding surface cool and flush away debris, resulting in cleaner cuts and more polished finishes.

The Wet Cutting Process

1. Wet Cutting Equipment:

To perform wet cutting on plate glass, specialized cutting tools are required. Diamond-tipped saws and cutters are typically used, as they can handle the hardness and brittleness of glass. These tools are designed to be submerged in or sprayed with water to keep them cool and prevent the glass from shattering.

2. How It Works:

During wet cutting, the glass is fed into a diamond blade or saw that is constantly lubricated by water. The water acts as a coolant, reducing heat buildup and preventing the glass from overheating and cracking. The result is a smoother, more precise cut with less dust and debris.

3. Applications:

Wet cutting is commonly used in industries such as construction, automotive, and interior design, where large plates of glass need to be cut to specific dimensions. This process is also ideal for cutting glass into intricate shapes or smaller pieces, particularly when a high level of detail is required.

The Wet Grinding Process

1. Wet Grinding Equipment:

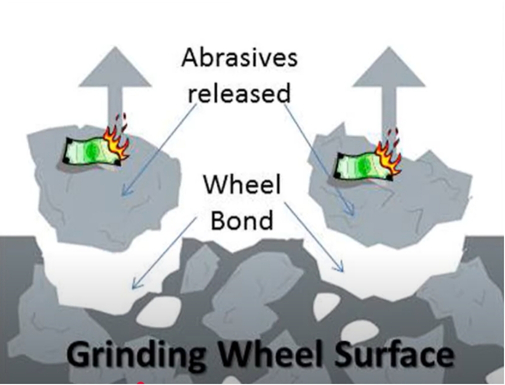

Wet grinding of plate glass involves specialized grinding wheels, usually made from abrasive materials like diamond or silicon carbide, which are used in combination with water. These grinding wheels are designed to smooth and polish the edges and surfaces of the glass after it has been cut.

2. How It Works:

The glass plate is held securely while the grinding wheel moves along its edges or surface. Water continuously flows over the glass, ensuring that the grinding wheel remains cool and that any glass particles created during the grinding process are washed away. This minimizes the risk of surface damage or the creation of cracks.

3. Applications:

Wet grinding is often used to refine the edges of glass after it has been cut, providing a smooth, polished finish. This process is particularly beneficial when working with glass for furniture, displays, or high-end architectural installations where the aesthetic appearance of the glass is paramount.

Benefits of Wet Cutting and Grinding

1. Reduced Risk of Cracking and Chipping:

The primary benefit of wet cutting and grinding is that the water acts as a coolant, preventing the glass from overheating. This reduces the likelihood of cracks or chips forming during the process, which can be a common problem with dry cutting.

2. Cleaner Cuts and Smoother Edges:

Water lubrication helps to remove debris and keep the cutting and grinding tools free from buildup. This results in cleaner, more precise cuts and smoother edges that require less post-processing work.

3. Extended Tool Life:

Using water during cutting and grinding helps to prolong the life of the tools. The constant lubrication reduces wear and tear on cutting blades and grinding wheels, making them more durable and cost-effective in the long run.

4. Enhanced Finish Quality:

Wet cutting and grinding typically yield a higher-quality finish compared to dry methods. The smoothness and clarity of the edges are especially important for glass used in visible or decorative applications, such as windows, mirrors, and tabletops.

5. SwarfBuster Additions:

During machining in glass fabrication, the particles become charged and like to stick and combine together on the tools, in the water circulation pipes and fall out boxes in filtration. SwarfBuster neutralizes the charge to reduce build up in the process system.

Best Practices for Wet Cutting and Grinding of Plate Glass

- Choose the Right Equipment:

Investing in high-quality diamond-tipped tools and grinding wheels is essential. These tools are designed specifically for cutting and grinding glass and will ensure the best results. Ensure the cutting equipment is capable of being used with water or has a built-in water supply system.

- Maintain Water Flow:

Make sure the water supply is constant and sufficient during both cutting and grinding. Lack of water can result in overheating, uneven cutting, and premature wear on the tools.

- Use Proper Safety Equipment:

Although wet cutting and grinding reduce the risk of dust and heat, personal protective equipment (PPE) is still important. Always wear safety goggles, gloves, and protective clothing to shield yourself from potential hazards like sharp edges or splinters.

- Test Cuts Before Full Operation:

Before starting on a large project, it’s wise to test the wet cutting and grinding setup on a small piece of glass. This helps ensure that the equipment is functioning correctly and that the water supply is adequate for the task at hand

- Regular Maintenance:

Routine maintenance of both the cutting and grinding equipment is crucial for consistent performance. Keep blades and wheels sharp and clean them after each use to prevent debris buildup and ensure a longer tool life. Adding SwarfBuster in a turbulent part of the water system directly after machining will aid in cleaner plumbing system reducing downtime.